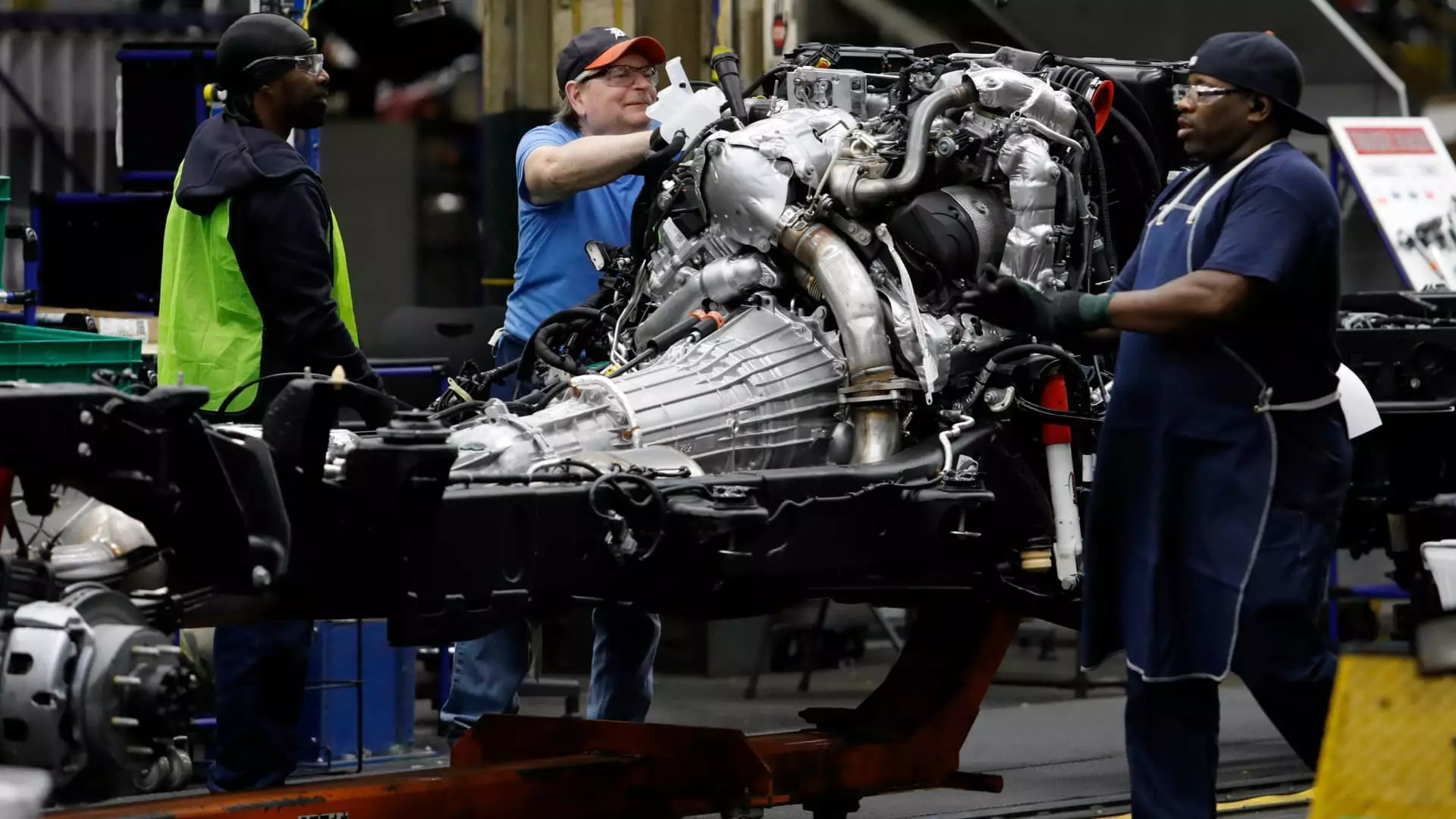

In a significant blow to General Motors (GM), the automaker has been compelled to suspend vehicle production at two of its plants in the United States due to supply chain complications stemming from Hurricane Helene. The affected locations include Flint, Michigan, known for its production of heavy-duty trucks, and Arlington, Texas, which specializes in full-size SUVs like the Chevrolet Tahoe and Cadillac Escalade. The decision to cancel shifts on Thursday and Friday highlights the direct repercussions of such natural disasters on manufacturing operations, which typically have intricate supply chains dependent on various external suppliers.

As of Friday morning, the company’s spokesperson refrained from providing specific timelines regarding when the affected facilities could resume normal operations. Recent communications sent to the Arlington workforce suggest that they may expect production to restart shortly on Monday, yet this remains tentative and subject to change based on the recovery of their supply chain partners. GM’s approach underscores the inherent uncertainty businesses face during crises, particularly when reliant on a web of suppliers that can be significantly disrupted by external forces like hurricanes.

Hurricane Helene’s impact was devastating, particularly in Florida and parts of North Carolina, where extensive damage has led to loss of life and displacements. As reported, the toll has climbed to at least 215 fatalities, along with numerous individuals still unaccounted for. The human aspect of such disasters transcends corporate interests, reminding us that behind the statistics are communities dealing with substantial losses and challenges. Such events necessitate corporate responsibility, where companies like GM must be transparent about how they are addressing the difficulties faced not just at their plants but also within their broader supply chain relationships.

Jeffrey Morrison, GM’s vice president of global purchasing and supply chain, pointed out that the disruptions caused by Hurricane Helene and concurrent port worker strikes revealed vulnerabilities within the automaker’s operational strategies. The end of the dockworker strike late Thursday provided a brief respite, yet the ongoing challenges necessitate continuing adaptation and resilience in GM’s sourcing and logistics strategies. Notably, Morrison’s insights into how the pandemic accelerated GM’s understanding of its supply chain underscore the importance of strategic foresight. Enhanced mapping of sub-tiers and improved dialogue with suppliers might enable the automaker to respond more effectively to similar disruptions in the future.

GM’s recent production stoppages due to Hurricane Helene serve as a stark reminder of the interconnectedness of modern supply chains and the vulnerabilities they may hold. While the company works diligently to navigate these challenges by strengthening relationships with suppliers and enhancing its operational intelligence, the events also illuminate broader themes of corporate resilience and community impact in the face of natural disasters. As companies continue to adapt, they must emphasize both operational efficiency and social responsibility, fostering environments not only for recovery but for sustainable growth in an ever-evolving landscape.